BHFUSE PPTC in Sensor Applications

With the increasing adoption of automation equipment, demands for counting, sensing, and identification have become more precise, making the role of sensors in automation systems even more critical.

Due to the diverse operating environments of sensors, requirements for waterproofing, oil resistance, and high-temperature stability are particularly stringent. As sensor sizes are constrained by the miniaturization of automation equipment and the limitations of other functional connectors, installation space is becoming increasingly limited, driving the need for further sensor miniaturization. This necessitates extremely compact designs, with some sensors occupying less than half the area of a thumb. Achieving both hardware and software processing functions within such a small circuit board space requires not only the use of miniature components but also a minimal number of them.

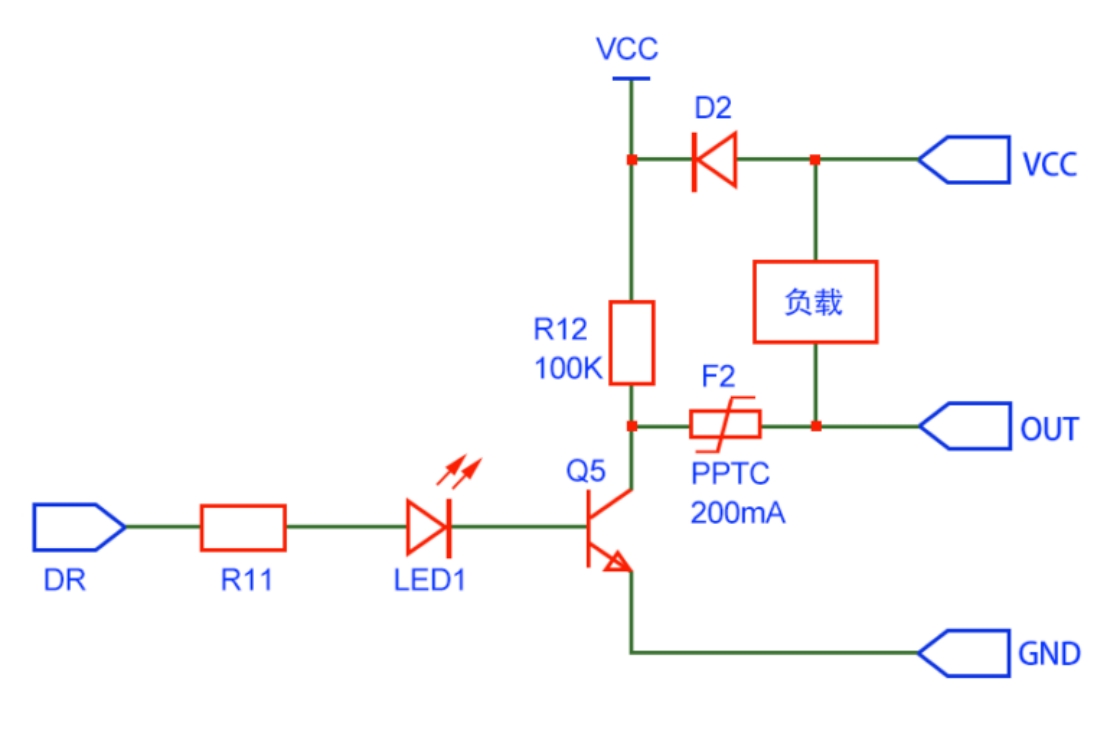

On the other hand, sensors are consumable items and often require manual replacement. Incorrect wiring by inexperienced personnel can easily lead to sensor circuit damage, making short-circuit protection essential. Given the limited PCB space, only a single passive component can be used to implement short-circuit protection. As a result, PPTC have become the preferred choice for engineers due to their small size and immunity to surge current effects. Typically, compact 0603-size PPTC with current ratings of 50mA to 200mA and voltage requirements of 24V to 36V are selected to meet the operational current range of sensors, which is between 5mA and 100mA.

Moreover, the usage scenarios of sensors are highly complex, imposing several requirements on PPTC :

1、The resistance of the PPTC must not change significantly after multiple soldering cycles.

2、Overcurrent protection must be fast to prevent damage to other components.

3、Resistance must not increase excessively during high-temperature operation.

4、Voltage resistance must not degrade after potting and hardening.

To address these industry-specific challenges, BHFUSE has developed products that exhibit minimal resistance variation after multiple soldering cycles and potting, low internal resistance, high-temperature resistance, fast protection, and stable resistance even after multiple protection events. These solutions meet customer demands while also providing professional design references and aging test data.