I. Core Concept: Why Do Medical Devices Need PPTC ?

Compared to traditional fuses, the unique value of PPTC lies in its "self-recovery" characteristic, which perfectly aligns with the fundamental needs of medical devices:

Ensuring Continuous Operation of Life Support Equipment: Devices such as ventilators, infusion pumps, and patient monitors can directly endanger patient lives if they unexpectedly shut down. PPTCs can automatically reset after an overcurrent fault is eliminated, avoiding treatment interruptions caused by fuse replacement and ensuring continuous device operation and patient monitoring.

Enhancing Safety Levels: PPTCs operate based on a solid-state resistance leap principle and do not generate electric arcs. This is a crucial explosion-proof design in operating room environments filled with oxygen and flammable anesthetic gases.

Achieving Maintenance-Free Operation and High Reliability: For implantable devices (e.g., pacemakers) or home-use devices for long-term patient use (e.g., CPAP machines), PPTCs provide lifelong, maintenance-free circuit protection, significantly improving device reliability.

Optimizing User Experience: Users of home medical devices are often ordinary patients or the elderly. If a fuse blows due to a momentary surge, users may be unable to resolve the issue. With PPTC protection, users only need to simply restart the device, greatly reducing the barrier to use.

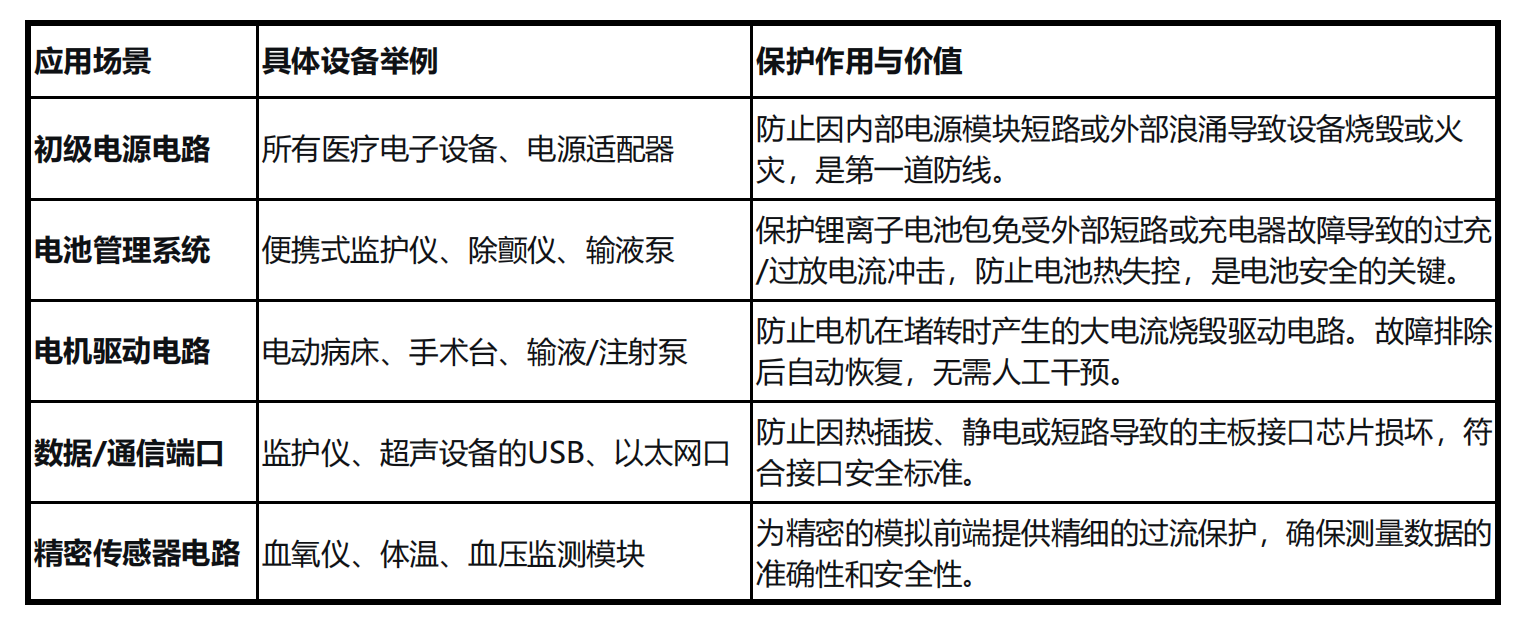

II. Analysis of Key Application Scenarios

PPTCs act as "Circuit Guardians" in medical devices, commonly found in the following critical areas:

III. Selection Guide: Special Considerations for Medical Grade

Selecting PPTCs for medical devices must adhere to standards far more stringent than those for consumer electronics:

1、Key Electrical Parameters:

Hold Current: Must be greater than the maximum peak current during normal circuit operation to prevent nuisance tripping.

Time-to-Trip: Must trip promptly before the protected components are damaged.

Maximum Operating Voltage: Must withstand the highest transient voltage present in the circuit.

Maximum Fault Current: Must be able to withstand and safely interrupt the maximum short-circuit current available from the power source.

2、Environment and Reliability:

Operating Temperature Range: Must consider the harsh environments the device might encounter, such as high temperatures near sterilizers or low temperatures during cold chain transport.

Endurance: Must be able to withstand multiple fault actions and reset cycles.

3、Certifications and Standards:

It is essential to choose PPTCs certified for medical device safety, with the core standard being UL/IEC 60601-1. This ensures the component meets the stringent medical-grade requirements for materials, construction, flame retardancy, and performance, guaranteeing that the final device can pass the overall system certification.

IV. Best Practices: Collaborative Protection Strategy

In high-end medical device design, PPTCs often form a "Defense-in-Depth" system with fuses:

Primary Protection (Coarse Protection): A fuse is used at the power input to handle the most extreme, catastrophic short-circuit faults, providing an absolutely reliable physical breakpoint.

Secondary Protection (Fine Protection): PPTCs are used at the front end of various subsystems and critical modules (e.g., battery, motor, ports) to handle common, recoverable overload and short-circuit faults.

This architecture leverages the absolute reliability of fuses under extreme fault conditions while utilizing the self-recovery advantages of PPTCs for routine faults, achieving the optimal balance between safety and availability.

Summary

The PPTC has evolved from a simple circuit protection component into a core embodiment of the high-reliability design philosophy in modern medical devices. Through its unique self-recovery characteristic, it plays an irreplaceable role in ensuring patient safety, enhancing device availability, and optimizing the user experience. Rigorous selection and collaborative protection design are key to ensuring the stable performance of PPTCs in life-critical medical equipment.